Emission Management

We strictly follow the Atmospheric Pollution Prevention and Control Law of the People's Republic of China, the Water Pollution Prevention and Control Law of the People's Republic of China, the Law of the People's Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste and the Regulation on the Administration of Permitting of Pollutant Discharges, among other laws and regulations. We have developed internal processes such as the Solid Waste Treatment and Disposal Procedures, the Waste Water and Waste Liquid Pollution Prevention and Control Management Measures, the Pollution Prevention and Control Management Measures, and the Energy and Water Conservation Management Measures. These processes outline the requirements, procedures, and content of clean production, as well as delineate the responsibilities of the personnel involved.

Waste Gas Management

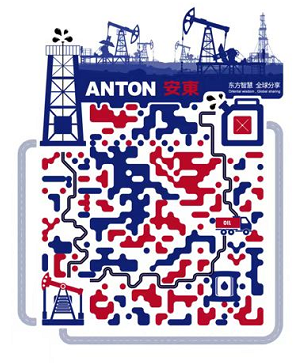

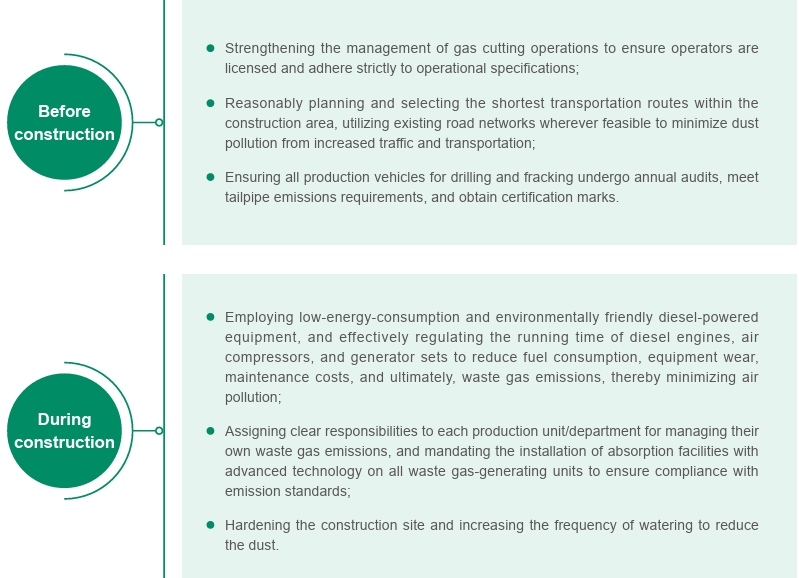

The Company rigorously adheres to the air pollution-related laws, regulations, and normative documents of the countries in which it operates, and tightly controls the emission of waste gas throughout all stages of its operations.

Methane (CH4 ), nitrogen oxides (NOX ), and sulfur oxides (SOX ) primarily stem from fuel-powered equipment and facilities used for drilling and production stimulation. Meanwhile, particulate matter mainly arises from dust generated by traffic and construction sites. In 2023, the company emits 1.49 tons of direct methane (CH4 ), 0.266 tons of nitrogen oxides (NOx ), and 0.202 tons of sulfur oxides (SOx ). To mitigate the emission of air pollutants across our various operations, we have implemented the following regulatory measures:

Case: T-ALL INSPECTION uses waste gas treatment facilities to reduce exhaust emission

In order to reduce gas emissions, T-ALL INSPECTION has strengthened management at the source, applied environmentally friendly paints, modified and upgraded equipment, and improved processes. In FY2023, T-ALL INSPECTION invested 6 sets of waste gas treatment devices in the production operation process. By using low VOCs waterborne paints in the closed plant, the waste gases in the spraying process are collected into the VOC waste gas treatment device through negative pressure, and then processed by the activated carbon-based tritiary filtration. As a result, the efficiency of non-methane hydrocarbons treatment reached 92%, and particulate matter treatment efficiency stands at 99%. The device helps to cut the emission of VOCs, and to ensure that the emission meets the environmental requirement, and thus minimize the pollution.

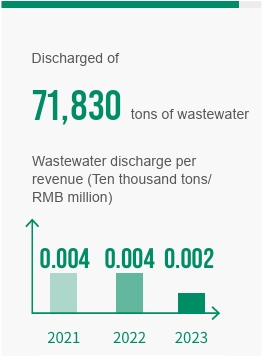

Wastewater Management

The Company maintains a stringent approach to wastewater management, ensuring compliance with laws, regulations, and norms governing domestic and industrial wastewater discharge. Through standardized management practices, enhanced equipment maintenance, and collective wastewater treatment techniques, we effectively handle all wastewater generated from drilling, fracking, and construction activities, ensuring safe disposal. Industrial and domestic wastewater is discharged in accordance with relevant standards, and we engage qualified third-party entities for the transportation and recycling of wastewater and waste liquid. These third-party entities are required to maintain archives and submit regular reports to ensure compliance.

In our daily operations, we enforce strict controls and inspections across all units to prevent on-site running, emitting, dripping, and leaking of wastewater, as well as to dewater sediment and waste liquid to prevent environmental pollution. During construction, we actively promote recycling and reutilization technologies, including the use of downhole operation wastewater for well washing and recycling fracturing flowback fluids, as part of our efforts to reduce wastewater discharge.

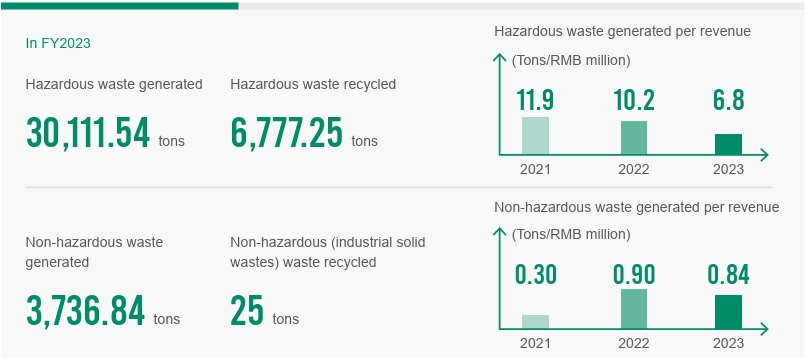

Waste Management

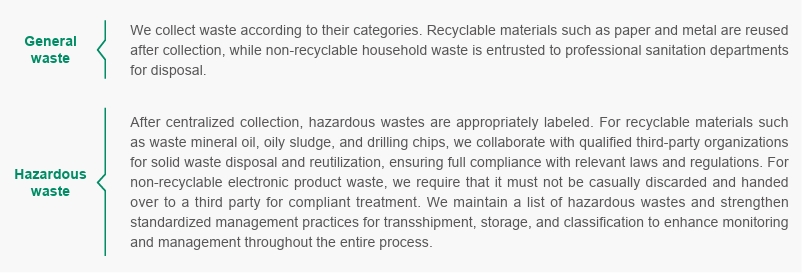

We strictly follow the Law of the People's Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste and the Standard for Pollution Control on Hazardous Waste Storage, among other laws and regulations. We developed internal processes such as the Solid Waste Treatment and Disposal Procedures. Our approach prioritizes waste reduction at the source, waste-to-resource conversion, and harmless treatment, ensuring compliant and effective waste management and disposal.

Based on the waste sources and disposal methods, we categorize waste into general waste and hazardous waste for targeted management:

Anton has set the objective of achieving 100% compliance with solid waste disposal each year. We employ clean production technologies, reduce the use of oil-based mud through layered drilling, promote drilling mud disposal technology and downhole oil removal technology during drilling operations, and implement clean production measures such as surface box workover operations. These initiatives significantly reduce solid waste, particularly hazardous waste.